Common popular models of metallized film capacitors

Common Popular Models of Metallized Film Capacitors

I. Introduction

Metallized film capacitors are essential components in modern electronic circuits, known for their reliability and versatility. These capacitors are widely used in various applications, from power electronics to consumer devices, due to their unique properties and advantages. This article aims to provide an in-depth understanding of metallized film capacitors, their construction, advantages, common types, popular models, and selection criteria, ultimately highlighting their significance in the electronics industry.

II. Understanding Metallized Film Capacitors

A. Construction and Materials

Metallized film capacitors consist of a thin film dielectric material, which is coated with a metallic layer. The most common dielectric materials used include:

1. **Polyester**: Known for its good electrical properties and cost-effectiveness, polyester film capacitors are widely used in various applications.

2. **Polypropylene**: This material offers excellent thermal stability and low dielectric losses, making it suitable for high-frequency applications.

3. **Polycarbonate**: Although less common today due to its higher cost, polycarbonate film capacitors are valued for their stability and reliability.

The metallization process typically involves depositing a thin layer of metal, such as aluminum or zinc, onto the dielectric film. This layer serves as one of the capacitor's electrodes, allowing for efficient charge storage.

B. Working Principle

The working principle of metallized film capacitors revolves around the storage of electrical energy in an electric field. When a voltage is applied across the capacitor, an electric field is created between the two electrodes (the metallized layer and the other electrode). The dielectric material plays a crucial role in determining the capacitance value, as it affects the capacitor's ability to store charge. The capacitance (C) is defined by the formula:

\[ C = \frac{\varepsilon \cdot A}{d} \]

Where:

- \( \varepsilon \) is the permittivity of the dielectric material,

- \( A \) is the area of the electrodes,

- \( d \) is the distance between the electrodes.

III. Advantages of Metallized Film Capacitors

Metallized film capacitors offer several advantages that make them a popular choice in various applications:

A. High Reliability and Stability

These capacitors are known for their long lifespan and stable performance over time. They can withstand environmental stressors, such as temperature fluctuations and humidity, without significant degradation.

B. Low Equivalent Series Resistance (ESR)

Metallized film capacitors exhibit low ESR, which minimizes energy losses during operation. This characteristic is particularly beneficial in high-frequency applications, where efficiency is crucial.

C. Excellent Temperature and Voltage Characteristics

These capacitors can operate effectively across a wide range of temperatures and voltage levels, making them suitable for diverse applications, from consumer electronics to industrial machinery.

D. Self-Healing Properties

One of the standout features of metallized film capacitors is their self-healing capability. In the event of a dielectric breakdown, the metallization layer can vaporize, effectively isolating the damaged area and allowing the capacitor to continue functioning.

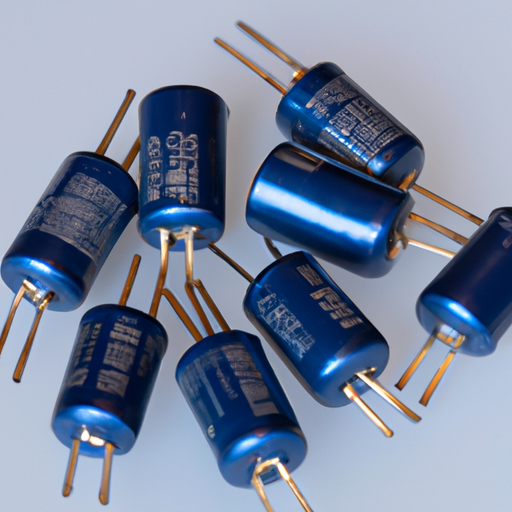

IV. Common Types of Metallized Film Capacitors

A. Polyester Film Capacitors

Polyester film capacitors are among the most widely used types due to their cost-effectiveness and decent performance. They are commonly found in applications such as:

- Power supplies

- Signal coupling

- Timing circuits

**Popular Models**:

WIMA MKS: Known for its compact size and reliability, the WIMA MKS series is suitable for various applications, including audio and power electronics.

KEMET R82: This series offers a wide capacitance range and is ideal for general-purpose applications.

B. Polypropylene Film Capacitors

Polypropylene film capacitors are favored for their superior electrical properties and low losses. They are often used in high-frequency applications, such as:

- Audio equipment

- RF circuits

- Motor run applications

**Popular Models**:

EPCOS B3292: This series is known for its high voltage ratings and low ESR, making it suitable for demanding applications.

Vishay MKP: The MKP series offers excellent performance in audio and power applications, with a focus on low losses.

C. Polycarbonate Film Capacitors

Although less common today, polycarbonate film capacitors are valued for their stability and reliability. They are often used in applications requiring high precision and stability, such as:

- Timing circuits

- Precision filters

**Popular Models**:

KEMET C4AE: This series is known for its high capacitance values and excellent temperature stability.

Vishay 1832: The 1832 series offers reliable performance in various applications, including industrial and consumer electronics.

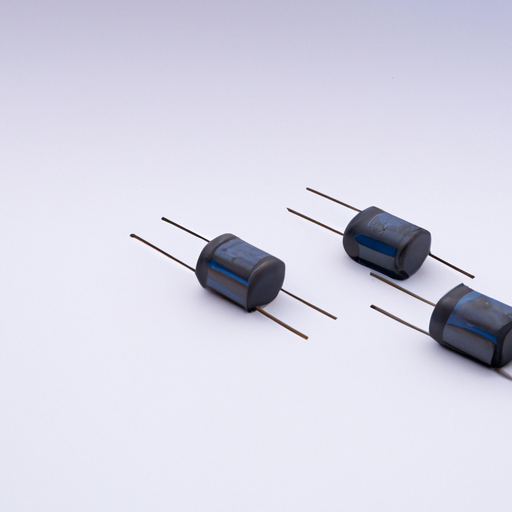

D. Other Specialized Types

1. **Metallized Paper Capacitors**: These capacitors are used in applications requiring high voltage and capacitance, such as power factor correction.

2. **High-Voltage Metallized Film Capacitors**: Designed for high-voltage applications, these capacitors are used in power electronics and renewable energy systems.

V. Key Manufacturers and Their Popular Models

A. Overview of Leading Manufacturers

Several manufacturers are recognized for their high-quality metallized film capacitors:

1. **WIMA**: Known for its innovative designs and reliable products, WIMA offers a wide range of film capacitors suitable for various applications.

2. **KEMET**: A leading manufacturer of capacitors, KEMET provides a diverse selection of metallized film capacitors with excellent performance characteristics.

3. **Vishay**: Vishay is renowned for its high-quality electronic components, including a variety of film capacitors designed for demanding applications.

4. **EPCOS**: A subsidiary of TDK, EPCOS specializes in capacitors and offers a range of metallized film capacitors known for their reliability.

B. Comparison of Popular Models from Each Manufacturer

When comparing popular models from these manufacturers, it's essential to consider specifications such as capacitance, voltage rating, and application suitability. For instance:

WIMA MKS vs. **KEMET R82**: Both offer excellent performance, but the WIMA MKS is often preferred for audio applications due to its compact size.

EPCOS B3292 vs. **Vishay MKP**: The EPCOS model is known for its high voltage ratings, while the Vishay MKP excels in low-loss applications.

VI. Applications of Metallized Film Capacitors

Metallized film capacitors find applications across various industries, including:

A. Power Electronics

In power electronics, these capacitors are used for energy storage, filtering, and power factor correction, ensuring efficient operation of power systems.

B. Audio Equipment

High-quality audio equipment often employs metallized film capacitors for signal coupling and filtering, enhancing sound quality and performance.

C. Industrial Machinery

In industrial settings, these capacitors are used in motor drives, control circuits, and power supplies, contributing to the reliability and efficiency of machinery.

D. Renewable Energy Systems

Metallized film capacitors play a crucial role in renewable energy systems, such as solar inverters and wind turbines, where they help manage energy storage and conversion.

E. Consumer Electronics

From televisions to smartphones, metallized film capacitors are integral to the performance of consumer electronics, ensuring stable operation and longevity.

VII. Selection Criteria for Metallized Film Capacitors

When selecting metallized film capacitors for a specific application, several criteria should be considered:

A. Capacitance Value and Tolerance

Choose a capacitance value that meets the requirements of your circuit, along with an appropriate tolerance level to ensure performance.

B. Voltage Rating

Ensure the voltage rating of the capacitor exceeds the maximum voltage it will encounter in the application to prevent breakdown.

C. Temperature Coefficient

Consider the temperature coefficient of the capacitor, as it affects performance in varying temperature conditions.

D. Size and Form Factor

Select a size and form factor that fits within the design constraints of your circuit while ensuring adequate performance.

E. Application-Specific Requirements

Evaluate any specific requirements related to the application, such as self-healing properties, ESR, and frequency response.

VIII. Conclusion

Metallized film capacitors are vital components in modern electronics, offering reliability, efficiency, and versatility across a wide range of applications. As technology continues to evolve, the demand for high-performance capacitors will only increase. Understanding the various types, popular models, and selection criteria will empower engineers and designers to make informed decisions in their projects. As we look to the future, advancements in capacitor technology will likely lead to even more innovative solutions in the electronics industry.

IX. References

For further reading on metallized film capacitors and electronic components, consider the following sources:

- "Capacitors: Technology and Applications" by John Smith

- "Electronic Components: A Complete Reference" by Jane Doe

- Manufacturer datasheets and technical documents from WIMA, KEMET, Vishay, and EPCOS.

By exploring these resources, you can deepen your understanding of capacitors and their role in electronic design.