What are the popular ceramic capacitor product types?

What are the Popular Ceramic Capacitor Product Types?

I. Introduction

Ceramic capacitors are essential components in modern electronic circuits, playing a crucial role in various applications ranging from consumer electronics to industrial machinery. These capacitors are made from ceramic materials that exhibit dielectric properties, allowing them to store and release electrical energy efficiently. Their popularity stems from their stability, reliability, and versatility, making them a preferred choice for engineers and designers. This article aims to explore the different types of ceramic capacitors, their characteristics, applications, and the factors to consider when selecting the right type for specific needs.

II. Types of Ceramic Capacitors

Ceramic capacitors can be classified based on various criteria, including dielectric material, capacitance value, and size/form factor. Understanding these classifications helps in selecting the appropriate capacitor for a given application.

A. Classification Based on Dielectric Material

1. **Class 1 Ceramic Capacitors**

- **Characteristics**: Class 1 ceramic capacitors are made from materials that provide stable capacitance over a wide range of temperatures and voltages. They typically have low dielectric losses and high insulation resistance. The most common dielectric material used in Class 1 capacitors is NP0 (C0G), which offers excellent temperature stability.

- **Applications**: These capacitors are ideal for applications requiring precision and stability, such as timing circuits, filters, and resonators. They are commonly used in RF (radio frequency) applications and high-frequency circuits.

2. **Class 2 Ceramic Capacitors**

- **Characteristics**: Class 2 ceramic capacitors, such as X7R and Y5V, have higher capacitance values but exhibit greater variations in capacitance with temperature, voltage, and time. They are made from materials that allow for a higher dielectric constant, resulting in smaller physical sizes for higher capacitance values.

- **Applications**: These capacitors are widely used in decoupling, bypassing, and coupling applications in consumer electronics, automotive systems, and power supply circuits. However, their less stable characteristics make them less suitable for precision applications.

B. Classification Based on Capacitance Value

1. **Low Capacitance Ceramic Capacitors**

- **Characteristics**: Low capacitance ceramic capacitors typically range from a few picofarads (pF) to several nanofarads (nF). They are often used in high-frequency applications due to their low equivalent series resistance (ESR) and high self-resonant frequency.

- **Applications**: These capacitors are commonly found in RF circuits, timing circuits, and signal coupling applications where minimal capacitance is required.

2. **High Capacitance Ceramic Capacitors**

- **Characteristics**: High capacitance ceramic capacitors can range from microfarads (µF) to hundreds of microfarads. They are designed to handle larger amounts of energy and are often used in power supply applications.

- **Applications**: These capacitors are used in applications such as power supply decoupling, energy storage, and filtering in various electronic devices, including computers, smartphones, and automotive electronics.

C. Classification Based on Size and Form Factor

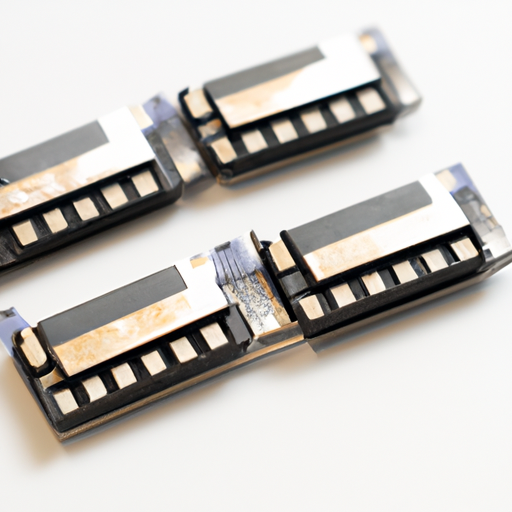

1. **Surface Mount Ceramic Capacitors (SMD)**

- **Characteristics**: SMD ceramic capacitors are designed for surface mounting on printed circuit boards (PCBs). They are compact and lightweight, making them suitable for high-density circuit designs. Their small size allows for automated assembly processes.

- **Applications**: SMD capacitors are widely used in consumer electronics, telecommunications, and automotive applications where space is a premium.

2. **Through-Hole Ceramic Capacitors**

- **Characteristics**: Through-hole ceramic capacitors have leads that pass through the PCB, providing a robust connection. They are generally larger than SMD capacitors and are often used in applications where mechanical stability is essential.

- **Applications**: These capacitors are commonly found in older electronic designs, power supplies, and applications requiring higher voltage ratings.

III. Key Features of Ceramic Capacitors

When selecting ceramic capacitors, several key features must be considered to ensure optimal performance in specific applications.

A. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. Exceeding this rating can lead to capacitor failure, so it is crucial to choose a capacitor with an appropriate voltage rating for the application.

B. Temperature Coefficient

The temperature coefficient describes how the capacitance value changes with temperature. Class 1 capacitors have a low temperature coefficient, making them suitable for precision applications, while Class 2 capacitors exhibit more significant variations.

C. Tolerance

Tolerance refers to the allowable deviation from the nominal capacitance value. It is essential to consider tolerance when selecting capacitors for applications requiring specific capacitance values.

D. Frequency Response

The frequency response of a capacitor indicates how its impedance changes with frequency. Ceramic capacitors generally have excellent high-frequency performance, making them suitable for RF applications.

IV. Popular Applications of Ceramic Capacitors

Ceramic capacitors are used in a wide range of applications due to their versatility and reliability.

A. Consumer Electronics

In consumer electronics, ceramic capacitors are commonly used in smartphones, tablets, and laptops for decoupling, filtering, and timing applications. Their small size and high capacitance values make them ideal for compact designs.

B. Automotive Applications

In the automotive industry, ceramic capacitors are used in various systems, including engine control units, infotainment systems, and safety features. Their reliability and ability to withstand harsh environmental conditions make them suitable for automotive applications.

C. Industrial Equipment

Ceramic capacitors are used in industrial equipment for power supply filtering, motor control, and signal processing. Their stability and performance under varying conditions are critical in industrial settings.

D. Telecommunications

In telecommunications, ceramic capacitors are used in base stations, routers, and other communication devices. Their high-frequency performance and reliability are essential for maintaining signal integrity.

V. Advantages and Disadvantages of Ceramic Capacitors

A. Advantages

1. **Stability and Reliability**: Ceramic capacitors offer excellent stability over a wide range of temperatures and voltages, making them reliable components in various applications.

2. **Small Size and Lightweight**: Their compact size allows for high-density circuit designs, making them ideal for modern electronic devices.

3. **Wide Range of Capacitance Values**: Ceramic capacitors are available in a broad range of capacitance values, catering to diverse application needs.

B. Disadvantages

1. **Voltage Dependency**: The capacitance value of ceramic capacitors, especially Class 2 types, can vary significantly with applied voltage, which may lead to performance issues in certain applications.

2. **Microphonics**: Ceramic capacitors can exhibit microphonic effects, where mechanical vibrations can induce electrical noise, potentially affecting sensitive circuits.

3. **Limited Capacitance in Class 1**: While Class 1 capacitors offer excellent stability, their capacitance values are generally lower than those of Class 2 capacitors, limiting their use in high-capacitance applications.

VI. Conclusion

In summary, ceramic capacitors are vital components in modern electronics, offering a range of types and characteristics to suit various applications. Understanding the different classifications, key features, and advantages and disadvantages of ceramic capacitors is essential for selecting the right type for specific needs. As technology continues to evolve, advancements in ceramic capacitor technology are expected, leading to even more efficient and reliable components. Selecting the appropriate ceramic capacitor type is crucial for ensuring optimal performance in electronic circuits, making it an important consideration for engineers and designers alike.

VII. References

For further exploration of ceramic capacitors, consider the following resources:

1. "Capacitors: Technology and Trends" by John Smith

2. "Understanding Ceramic Capacitors" - Electronics Tutorials

3. "The Role of Capacitors in Electronic Circuits" - IEEE Xplore

4. Manufacturer datasheets for specific ceramic capacitor products

By delving into these resources, readers can gain a deeper understanding of ceramic capacitors and their applications in the ever-evolving world of electronics.