Mainstream capacitors and product series parameters

Mainstream Capacitors and Product Series Parameters

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from filtering signals to stabilizing voltage levels. Understanding the different types of capacitors and their parameters is essential for engineers and designers to select the right components for their projects. This article will delve into mainstream capacitors, exploring their types, key parameters, product series, and the latest trends in capacitor technology.

II. Types of Capacitors

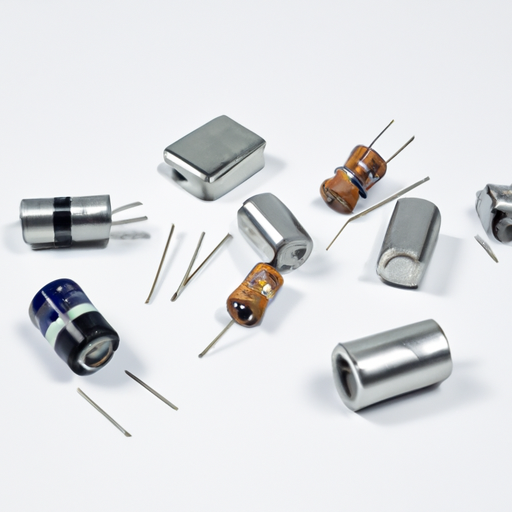

Capacitors come in various types, each with unique characteristics and applications. Here, we will discuss five mainstream types of capacitors: electrolytic, ceramic, film, tantalum, and supercapacitors.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that typically have a high capacitance value. They are constructed using an electrolyte, which allows for a larger capacitance in a smaller volume.

**Characteristics:**

- High capacitance values (typically in the microfarad to millifarad range)

- Polarized, meaning they must be connected in the correct direction

- Relatively high Equivalent Series Resistance (ESR)

**Common Applications:**

Electrolytic capacitors are widely used in power supply circuits, audio equipment, and decoupling applications due to their ability to store large amounts of energy.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are known for their stability and reliability.

**Characteristics:**

- Available in a wide range of capacitance values (from picofarads to microfarads)

- Low ESR and high-frequency performance

- Non-polarized, allowing for flexible circuit design

**Common Applications:**

These capacitors are commonly used in RF applications, decoupling, and timing circuits due to their stability and low losses.

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their excellent performance and reliability.

**Characteristics:**

- Low ESR and ESL (Equivalent Series Inductance)

- High voltage ratings

- Non-polarized

**Common Applications:**

Film capacitors are often used in audio applications, power electronics, and timing circuits due to their stability and low distortion.

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, but they use tantalum metal as the anode. They are known for their high capacitance and reliability.

**Characteristics:**

- High capacitance values in a small package

- Stable performance over a wide temperature range

- Polarized

**Common Applications:**

Tantalum capacitors are commonly found in portable electronics, medical devices, and military applications due to their reliability and compact size.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They can store a significant amount of energy and release it quickly.

**Characteristics:**

- Very high capacitance values (from farads to thousands of farads)

- Fast charge and discharge cycles

- Long cycle life

**Common Applications:**

Supercapacitors are used in applications requiring rapid bursts of energy, such as in regenerative braking systems, energy harvesting, and backup power supplies.

III. Key Parameters of Capacitors

When selecting capacitors for a specific application, several key parameters must be considered. Understanding these parameters is crucial for ensuring optimal performance in electronic circuits.

A. Capacitance Value

**Definition and Measurement:**

Capacitance is the ability of a capacitor to store an electrical charge, measured in farads (F). It is typically expressed in microfarads (µF), nanofarads (nF), or picofarads (pF).

**Importance in Circuit Design:**

The capacitance value directly affects the performance of the circuit. For example, in timing circuits, the capacitance value determines the timing interval, while in filtering applications, it influences the cutoff frequency.

B. Voltage Rating

**Definition and Significance:**

The voltage rating indicates the maximum voltage a capacitor can handle without breaking down. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage it will encounter in the circuit.

**Consequences of Exceeding Voltage Ratings:**

Exceeding the voltage rating can lead to capacitor failure, which may result in circuit malfunction or damage to other components.

C. Tolerance

**Definition and Types:**

Tolerance refers to the allowable variation in capacitance value from the specified value. It is usually expressed as a percentage. Common tolerances include ±5%, ±10%, and ±20%.

**Impact on Circuit Performance:**

A capacitor with a tighter tolerance will provide more consistent performance in critical applications, while a wider tolerance may be acceptable in less sensitive circuits.

D. Equivalent Series Resistance (ESR)

**Definition and Measurement:**

ESR is the internal resistance of a capacitor that affects its performance, especially in high-frequency applications. It is measured in ohms (Ω).

**Importance in High-Frequency Applications:**

Low ESR is crucial for applications such as power supply decoupling, where high-frequency performance is essential. High ESR can lead to power loss and reduced efficiency.

E. Temperature Coefficient

**Definition and Types:**

The temperature coefficient indicates how the capacitance value changes with temperature. Different types of capacitors have different temperature coefficients, such as C0G, X7R, and Y5V.

**Effects on Performance in Varying Temperatures:**

Understanding the temperature coefficient is essential for applications exposed to varying temperatures, as it can significantly impact the capacitor's performance.

IV. Product Series Parameters

A. Overview of Product Series

**Definition and Significance:**

Manufacturers categorize capacitors into product series based on their specifications, performance characteristics, and intended applications. This categorization helps engineers select the right components for their designs.

B. Common Product Series Examples

**Series from Major Manufacturers:**

1. **Panasonic:** Known for their EEH series of electrolytic capacitors, which offer high capacitance and low ESR.

2. **Vishay:** Their 1812 series of ceramic capacitors is popular for its reliability and performance in various applications.

3. **KEMET:** The KPS series of tantalum capacitors is recognized for its compact size and high reliability.

**Key Specifications and Features of Each Series:**

Each product series comes with specific features, such as voltage ratings, capacitance values, and temperature coefficients, making it essential to review the datasheets for detailed information.

C. Selection Criteria for Product Series

**Application Requirements:**

When selecting a product series, consider the specific requirements of the application, such as capacitance value, voltage rating, and size constraints.

**Environmental Considerations:**

Factors such as temperature, humidity, and exposure to chemicals can influence the choice of capacitor series. For example, capacitors used in automotive applications may require higher temperature ratings.

**Cost vs. Performance Trade-offs:**

Balancing cost and performance is crucial in capacitor selection. While high-performance capacitors may offer better reliability, they can also be more expensive. Engineers must evaluate the trade-offs based on the project's budget and requirements.

V. Trends in Capacitor Technology

A. Advancements in Materials

**New Dielectric Materials:**

Recent advancements in dielectric materials have led to improved performance and reliability in capacitors. For example, the development of high-k dielectrics allows for smaller capacitors with higher capacitance values.

**Impact on Performance and Reliability:**

These advancements enhance the overall performance of capacitors, making them suitable for demanding applications in modern electronics.

B. Miniaturization and High-Density Capacitors

**Trends in Size Reduction:**

As electronic devices become smaller and more compact, the demand for miniaturized capacitors has increased. Manufacturers are developing high-density capacitors that offer higher capacitance in smaller packages.

**Applications in Modern Electronics:**

Miniaturized capacitors are essential in smartphones, wearables, and other compact devices, enabling manufacturers to create thinner and lighter products.

C. Sustainability and Eco-Friendly Capacitors

**Development of Greener Alternatives:**

The electronics industry is increasingly focusing on sustainability, leading to the development of eco-friendly capacitors. These capacitors use environmentally friendly materials and processes, reducing their impact on the environment.

**Industry Initiatives for Sustainability:**

Many manufacturers are adopting sustainable practices, such as reducing waste and energy consumption in production, to meet the growing demand for environmentally responsible products.

VI. Conclusion

Understanding the various types of capacitors and their parameters is essential for anyone involved in electronic design. From selecting the right capacitor for a specific application to keeping up with the latest trends in technology, knowledge of capacitors is crucial for ensuring optimal performance in electronic circuits. As technology continues to evolve, the future of capacitor technology looks promising, with advancements in materials, miniaturization, and sustainability paving the way for innovative solutions in the electronics industry. For those interested in further exploration, delving into the specifications and applications of different capacitor types can provide valuable insights into this vital component of modern electronics.

VII. References

1. Manufacturer datasheets from Panasonic, Vishay, and KEMET.

2. Academic papers on capacitor technology and applications.

3. Industry articles discussing trends in capacitor design and materials.

By understanding the intricacies of capacitors, engineers and designers can make informed decisions that enhance the performance and reliability of their electronic circuits.