Let me show you the internal structure of mainstream resistors, which many people don't know

46

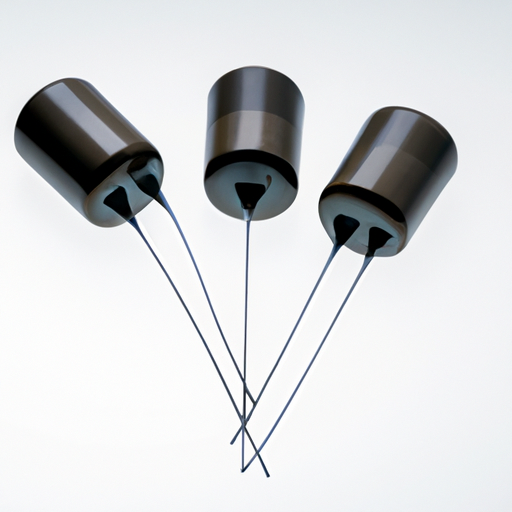

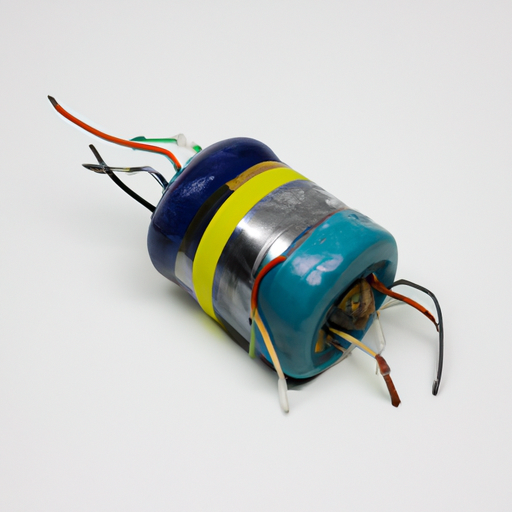

Resistors are generally directly called resistors in daily life. It is a current limiting element. After connecting the resistor in the circuit, the resistance value of the resistor is fixed, usually two pins, which can limit the current through the branch connected to it. Those whose resistance cannot be changed are called fixed resistors. Those with variable resistance are called potentiometers or variable resistors. The ideal resistor is linear, that is, the instantaneous current passing through the resistor is proportional to the applied instantaneous voltage. Variable resistor for voltage division. On the exposed resistor, one or two movable metal contacts are pressed tightly. The contact position determines the resistance between either end of the resistor and the contact. According to the classification of materials, resistors can be basically divided into five types of resistors, including wire wound resistors, carbon synthetic resistors, carbon film resistors, metal film resistors and metal oxide film resistors. I will show you the internal structure of mainstream resistors through five kinds of resistors. Wire wound resistors are made by winding resistance wires. Resistors are made by winding high resistance alloy wires on the insulation skeleton, and are coated with heat-resistant glaze insulation layer or insulating paint. Winding resistance has low temperature coefficient, high resistance accuracy, good stability, heat resistance and corrosion resistance. It is mainly used as precision high-power resistance. Its disadvantages are poor high-frequency performance and large time constant. First of all, the wire wound resistor is to wind the nickel chromium alloy wire on the alumina ceramic substrate, and control the resistance circle by circle. The winding resistance can be made into a precision resistance with a tolerance of 0.005%. At the same time, the temperature coefficient is very low. The disadvantage is that the parasitic inductance of the winding resistance is relatively large and cannot be used in high frequency. The volume of the wound resistor can be made very large, and then add an external radiator, which can be used as a high-power resistor. Secondly, the carbon synthetic resistor is made of carbon and synthetic plastic. The concentration of carbon powder determines the resistance value. Tin plated copper leads are added at both ends, and finally packaged. The carbon film resistor is made by plating a layer of carbon on the ceramic tube and depositing the crystalline carbon on the ceramic rod skeleton. Carbon film resistor is the most widely used resistor at present because of its low cost, stable performance, wide resistance range and low temperature coefficient and voltage coefficient. In order to control the resistance more accurately, spiral grooves can be machined on the carbon film. The more spirals, the greater the resistance; Finally, metal leads are added, and resin packaging is formed. The process of carbon film resistor is a little more complicated, and it can be used as a precision resistor. However, due to the carbon quality, the temperature characteristic is still not very good. The metal film resistor is formed by coating a layer of metal on the ceramic tube, and the alloy material is evaporated on the surface of the ceramic rod skeleton by vacuum evaporation. Compared with carbon film resistance, metal film resistance has higher accuracy, better stability, lower noise and temperature coefficient. It is widely used in instruments and communication equipment. Finally, the metal oxide film resistor is formed by plating a layer of tin oxide on the porcelain tube and depositing a layer of metal oxide on the insulating rod. Because it is an oxide itself, it is stable at high temperature, resistant to heat shock, and has strong load capacity. According to its purpose, it has general purpose, precision, high frequency, high voltage, high resistance, high power and resistance network.

Read more

Sale

Sale Sale

Sale Sale

Sale Sale

Sale Sale

Sale