What are the product characteristics of aluminum capacitors?

What are the Product Characteristics of Aluminum Capacitors?

I. Introduction

Aluminum capacitors are a vital component in modern electronic circuits, playing a crucial role in energy storage and signal processing. These capacitors are widely used due to their unique properties, which make them suitable for various applications, from consumer electronics to industrial machinery. In this article, we will explore the product characteristics of aluminum capacitors, including their structure, key features, performance metrics, applications, advantages, and disadvantages.

II. Basic Structure of Aluminum Capacitors

A. Anode and Cathode

Aluminum capacitors consist of two main electrodes: the anode and the cathode. The anode is typically made of aluminum foil, which is oxidized to form a thin layer of aluminum oxide. This oxide layer acts as a dielectric, allowing the capacitor to store electrical energy. The cathode is usually composed of a liquid or solid electrolyte, which facilitates the flow of electric current.

1. Role of Aluminum Oxide Layer

The aluminum oxide layer is critical to the capacitor's functionality. It provides insulation between the anode and cathode while allowing the capacitor to maintain a high capacitance value. The thickness of this oxide layer can be controlled during manufacturing, influencing the capacitor's voltage rating and overall performance.

2. Electrolyte Composition

The electrolyte in aluminum capacitors can vary, with common types including aqueous solutions of salts or organic solvents. The choice of electrolyte affects the capacitor's performance characteristics, such as its equivalent series resistance (ESR) and temperature stability.

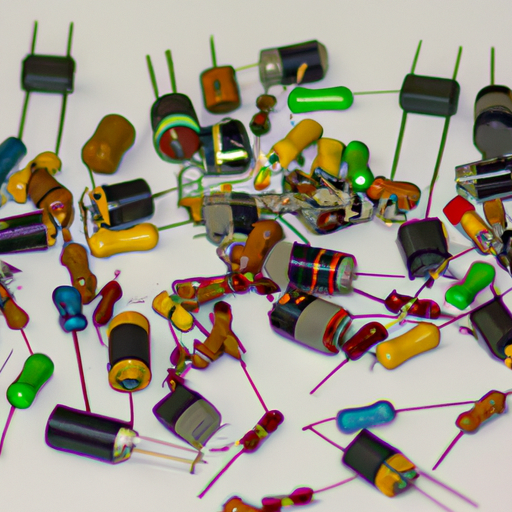

B. Types of Aluminum Capacitors

Aluminum capacitors can be categorized into several types, each designed for specific applications.

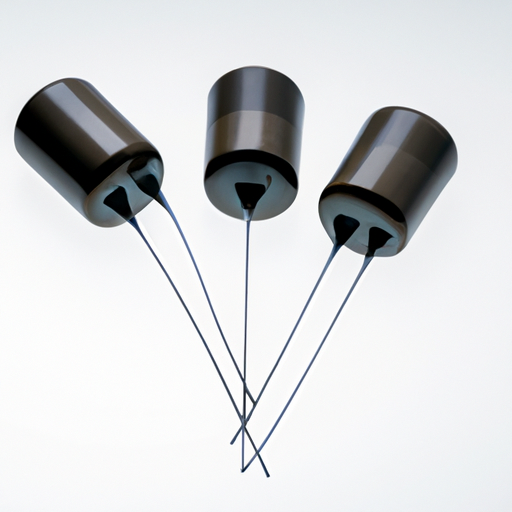

1. Electrolytic Capacitors

Electrolytic capacitors are the most common type of aluminum capacitor. They are polarized, meaning they have a positive and negative terminal, and are typically used in applications requiring high capacitance values.

2. Non-Polarized Capacitors

Non-polarized aluminum capacitors can be connected in either direction, making them suitable for AC applications. They are often used in audio equipment and signal processing circuits.

3. Specialty Capacitors

Specialty aluminum capacitors are designed for specific applications, such as high-temperature environments or high-frequency circuits. These capacitors may have unique construction features to enhance their performance in demanding conditions.

III. Key Product Characteristics

A. Capacitance Value

The capacitance value of a capacitor is a measure of its ability to store electrical energy. It is typically expressed in farads (F), microfarads (µF), or picofarads (pF).

1. Measurement Units (Farads, Microfarads)

Capacitance values can range from a few picofarads to several thousand microfarads, depending on the type and application of the capacitor.

2. Range of Capacitance Values

Aluminum capacitors are available in a wide range of capacitance values, making them suitable for various applications, from filtering and decoupling to energy storage in power supply circuits.

B. Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage it can handle without failing.

1. Definition and Importance

Exceeding the voltage rating can lead to dielectric breakdown, resulting in capacitor failure. Therefore, selecting a capacitor with an appropriate voltage rating for the application is crucial.

2. Derating Factors

It is common practice to derate capacitors, meaning they are used at a voltage lower than their maximum rating to enhance reliability and lifespan. Factors such as temperature, frequency, and ripple current should be considered when determining the appropriate derating.

C. Equivalent Series Resistance (ESR)

ESR is a measure of the internal resistance of a capacitor, which affects its performance, especially in high-frequency applications.

1. Definition and Impact on Performance

A lower ESR indicates better performance, as it reduces power loss and heat generation during operation. High ESR can lead to inefficiencies and reduced performance in circuits.

2. Importance in High-Frequency Applications

In high-frequency applications, such as switching power supplies, low ESR is essential to ensure efficient energy transfer and minimize signal distortion.

D. Temperature Coefficient

The temperature coefficient of a capacitor indicates how its capacitance value changes with temperature.

1. Impact of Temperature on Performance

Temperature variations can affect the performance of aluminum capacitors, leading to changes in capacitance, ESR, and leakage current.

2. Operating Temperature Range

Aluminum capacitors typically have an operating temperature range of -40°C to +105°C, although some specialty capacitors can operate at higher temperatures.

E. Lifetime and Reliability

The lifespan of aluminum capacitors is influenced by several factors, including temperature, voltage, and ripple current.

1. Factors Affecting Lifespan

High temperatures and voltages can accelerate aging and degradation, leading to reduced reliability and eventual failure.

2. Failure Mechanisms

Common failure mechanisms include electrolyte evaporation, dielectric breakdown, and corrosion of the aluminum anode. Understanding these mechanisms is essential for selecting the right capacitor for a specific application.

IV. Performance Characteristics

A. Frequency Response

The frequency response of a capacitor refers to how its impedance changes with frequency.

1. Impedance Characteristics

Aluminum capacitors exhibit different impedance characteristics at various frequencies, which can affect their performance in AC circuits.

2. Applications in AC Circuits

In AC applications, capacitors are used for filtering, coupling, and decoupling signals, making their frequency response a critical factor in circuit design.

B. Ripple Current Handling

Ripple current refers to the AC component of the current flowing through a capacitor.

1. Definition and Importance

The ability of a capacitor to handle ripple current is crucial in power supply applications, where fluctuating currents can lead to overheating and failure.

2. Applications in Power Supply Circuits

Aluminum capacitors are commonly used in power supply circuits to smooth out voltage fluctuations and provide stable power to electronic components.

C. Leakage Current

Leakage current is the small amount of current that flows through a capacitor even when it is not connected to a circuit.

1. Definition and Measurement

Leakage current is typically measured in microamperes (µA) and can impact the overall performance of a circuit.

2. Impact on Circuit Performance

Excessive leakage current can lead to energy loss and reduced efficiency, making it an important consideration in capacitor selection.

V. Applications of Aluminum Capacitors

Aluminum capacitors are used in a wide range of applications, including:

A. Consumer Electronics

From televisions to smartphones, aluminum capacitors are essential for energy storage and signal processing in consumer electronics.

B. Industrial Equipment

In industrial settings, aluminum capacitors are used in motor drives, power supplies, and control systems, where reliability and performance are critical.

C. Automotive Applications

Aluminum capacitors play a vital role in automotive electronics, including power management systems, infotainment, and safety features.

D. Renewable Energy Systems

In renewable energy systems, such as solar inverters and wind turbines, aluminum capacitors are used for energy storage and power conditioning.

VI. Advantages and Disadvantages

A. Advantages

1. Cost-Effectiveness

Aluminum capacitors are generally more affordable than other types of capacitors, making them a popular choice for various applications.

2. High Capacitance Density

They offer high capacitance values in a relatively small package, making them suitable for space-constrained applications.

3. Availability

Aluminum capacitors are widely available, with numerous manufacturers producing a variety of types and specifications.

B. Disadvantages

1. Limited Voltage Ratings

Aluminum capacitors typically have lower voltage ratings compared to other capacitor types, which can limit their use in high-voltage applications.

2. Sensitivity to Temperature and Voltage

These capacitors can be sensitive to temperature and voltage variations, which can affect their performance and lifespan.

3. Aging and Degradation

Over time, aluminum capacitors can degrade, leading to reduced performance and eventual failure.

VII. Conclusion

In summary, aluminum capacitors are essential components in modern electronic circuits, offering a range of product characteristics that make them suitable for various applications. Understanding these characteristics, including capacitance value, voltage rating, ESR, temperature coefficient, and lifetime, is crucial for selecting the right capacitor for a specific application. As technology continues to evolve, advancements in aluminum capacitor technology will likely lead to improved performance and reliability, further solidifying their importance in the electronics industry.

VIII. References

- Academic Journals

- Industry Standards

- Manufacturer Specifications

This comprehensive overview of aluminum capacitors highlights their significance in electronic circuits and provides valuable insights into their product characteristics, performance metrics, and applications. Understanding these factors is essential for engineers and designers working in the field of electronics.