What components and modules does the capacitor housing contain?

What Components and Modules Does the Capacitor Housing Contain?

I. Introduction

Capacitors are essential components in modern electronics, serving as energy storage devices that play a critical role in various applications, from power supply systems to signal processing. At the heart of every capacitor lies its housing, which not only protects the internal components but also influences the capacitor's performance and reliability. Understanding the components and modules contained within capacitor housing is crucial for engineers, designers, and anyone involved in electronics. This article will explore the basic structure of capacitor housing, its key components, additional modules, specialized designs, manufacturing considerations, and future trends.

II. Basic Structure of Capacitor Housing

A. Description of Capacitor Housing

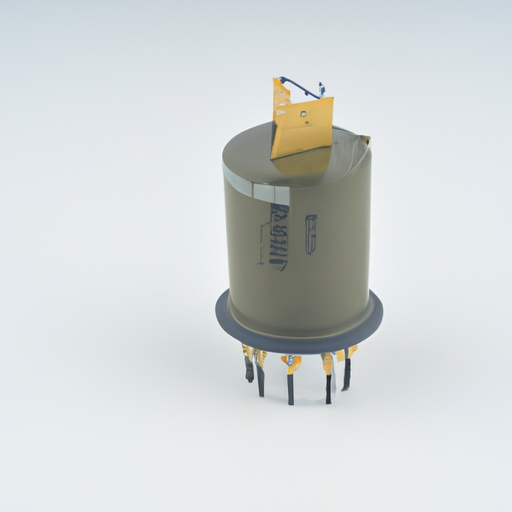

Capacitor housing is the outer shell that encases the internal components of a capacitor. It is designed to provide mechanical support and protection against environmental factors.

1. **Materials Used**: Capacitor housings are typically made from materials such as plastic, aluminum, or ceramic. The choice of material depends on the capacitor's application, voltage rating, and environmental conditions. For instance, aluminum is often used for electrolytic capacitors due to its excellent conductivity and lightweight properties.

2. **Physical Dimensions and Shapes**: Capacitor housings come in various shapes and sizes, including cylindrical, rectangular, and flat designs. The dimensions are influenced by the capacitor's capacitance value, voltage rating, and intended application.

B. Purpose of the Housing

The housing serves several critical functions:

1. **Protection**: It shields the internal components from physical damage, moisture, dust, and other environmental hazards.

2. **Insulation**: The housing provides electrical insulation, preventing short circuits and ensuring safe operation.

3. **Thermal Management**: Capacitors can generate heat during operation, and the housing plays a role in dissipating this heat to maintain optimal performance.

III. Key Components of Capacitor Housing

A. Capacitor Elements

The core components of a capacitor housed within its casing include:

1. **Dielectric Material**: The dielectric is a non-conductive material that separates the conductive plates and stores electrical energy.

a. **Types of Dielectrics**: Common dielectric materials include ceramic, electrolytic, and film. Each type has unique properties that affect capacitance, voltage rating, and temperature stability.

b. **Role of Dielectric in Capacitance**: The dielectric constant of the material directly influences the capacitor's ability to store charge. Higher dielectric constants result in greater capacitance.

2. **Conductive Plates**: These plates are responsible for storing electrical energy.

a. **Types of Conductive Materials**: Common materials include aluminum, tantalum, and copper. The choice of material affects the capacitor's performance, including its equivalent series resistance (ESR) and lifespan.

b. **Functionality in Energy Storage**: The conductive plates work in conjunction with the dielectric to create an electric field, allowing the capacitor to store energy.

B. Terminals and Connectors

The terminals and connectors are critical for integrating the capacitor into electronic circuits.

1. **Types of Terminals**: Capacitors may feature screw terminals, solder terminals, or surface-mount technology (SMT) pads. The choice depends on the application and mounting requirements.

2. **Importance of Connection Quality**: High-quality connections are essential for minimizing resistance and ensuring reliable performance. Poor connections can lead to overheating and failure.

C. Encapsulation Materials

Encapsulation materials protect the internal components from environmental factors.

1. **Types of Encapsulation**: Common encapsulation materials include epoxy and resin. These materials provide a barrier against moisture and contaminants.

2. **Role in Environmental Protection**: Encapsulation enhances the durability and longevity of capacitors, especially in harsh environments.

IV. Additional Modules in Capacitor Housing

A. Safety Features

Safety is paramount in capacitor design, and several features are incorporated into the housing:

1. **Pressure Relief Mechanisms**: These mechanisms prevent the buildup of internal pressure, which can occur due to gas generation during failure. They allow for safe venting of gases.

2. **Fuses and Circuit Protection**: Some capacitors include built-in fuses or circuit protection devices to prevent catastrophic failure and protect downstream components.

B. Monitoring and Control Modules

Modern capacitors may include advanced monitoring capabilities:

1. **Sensors for Temperature and Voltage**: Integrated sensors can monitor the operating conditions of the capacitor, providing real-time data for performance assessment.

2. **Integrated Circuitry for Performance Monitoring**: Some capacitors feature built-in circuitry that can communicate with external systems, allowing for enhanced control and diagnostics.

C. Thermal Management Systems

Effective thermal management is crucial for capacitor performance:

1. **Heat Sinks and Cooling Mechanisms**: Capacitors may be equipped with heat sinks or other cooling solutions to dissipate heat generated during operation.

2. **Importance of Thermal Regulation**: Proper thermal management ensures that capacitors operate within their specified temperature ranges, enhancing reliability and lifespan.

V. Specialized Capacitor Housing Designs

A. High-Voltage Capacitors

High-voltage capacitors require unique housing designs to ensure safety and performance:

1. **Unique Housing Requirements**: These capacitors often feature thicker insulation and specialized materials to withstand high voltages.

2. **Insulation and Safety Considerations**: Safety is critical, as failure can lead to dangerous situations. High-voltage capacitors may include additional safety features, such as reinforced housings.

B. Power Electronics Capacitors

Capacitors used in power electronics have specific design considerations:

1. **Design for High-Frequency Applications**: These capacitors must be optimized for high-frequency operation, which can affect housing design and materials.

2. **Impact on Housing Design**: The need for low inductance and resistance may lead to unique housing shapes and configurations.

C. Automotive and Aerospace Capacitors

Capacitors used in automotive and aerospace applications face unique challenges:

1. **Environmental Challenges**: These capacitors must withstand extreme temperatures, vibrations, and humidity.

2. **Housing Adaptations for Specific Applications**: Specialized housings may be required to meet the rigorous standards of these industries, including enhanced sealing and shock resistance.

VI. Manufacturing Considerations

A. Production Techniques for Capacitor Housing

The manufacturing process for capacitor housing involves several techniques:

1. **Injection Molding**: This technique is commonly used for producing plastic housings, allowing for complex shapes and high-volume production.

2. **Extrusion and Machining**: Aluminum and other metal housings may be produced through extrusion or machining processes, ensuring precise dimensions and finishes.

B. Quality Control Measures

Ensuring the reliability and performance of capacitors requires stringent quality control:

1. **Testing for Durability and Performance**: Capacitors undergo various tests, including thermal cycling, voltage stress, and mechanical stress tests.

2. **Compliance with Industry Standards**: Manufacturers must adhere to industry standards, such as IEC and UL, to ensure safety and performance.

VII. Future Trends in Capacitor Housing Design

A. Advances in Materials Science

The future of capacitor housing design is being shaped by advances in materials science:

1. **Nanomaterials and Their Impact**: The use of nanomaterials can enhance the performance and durability of capacitors, leading to smaller and more efficient designs.

2. **Biodegradable Options**: As sustainability becomes a priority, the development of biodegradable materials for capacitor housings is gaining attention.

B. Smart Capacitor Technologies

The integration of smart technologies is transforming capacitor design:

1. **Integration with IoT**: Capacitors may be equipped with IoT capabilities, allowing for remote monitoring and control.

2. **Enhanced Monitoring Capabilities**: Future capacitors may feature advanced monitoring systems that provide real-time data on performance and health.

VIII. Conclusion

Understanding the components and modules contained within capacitor housing is essential for anyone involved in electronics. From the basic structure and key components to specialized designs and future trends, each aspect plays a vital role in the performance and reliability of capacitors. As technology continues to evolve, so too will the design and functionality of capacitor housings, paving the way for more efficient and innovative electronic devices.

IX. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications

This comprehensive overview of capacitor housing components and modules highlights the complexity and importance of these devices in modern electronics. By staying informed about advancements and trends, professionals can better design and utilize capacitors in their applications.