What are the product standards for inductors?

What are the Product Standards for Inductors?

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, including power supplies, filters, and oscillators. As the demand for reliable and efficient electronic devices continues to grow, the importance of adhering to product standards for inductors becomes increasingly significant. These standards ensure that inductors meet specific performance criteria, safety requirements, and quality benchmarks, ultimately contributing to the overall reliability of electronic systems.

II. Types of Inductors

Inductors come in various types, each designed for specific applications and performance characteristics. Understanding these types is essential for selecting the right inductor for a given application.

A. Air-core Inductors

Air-core inductors are constructed without a magnetic core, relying solely on the air surrounding the coil to provide inductance. They are typically used in high-frequency applications due to their low losses and high self-resonant frequency.

B. Iron-core Inductors

Iron-core inductors utilize a ferromagnetic core to enhance inductance. The core material increases the magnetic field strength, allowing for higher inductance values in a smaller physical size. These inductors are commonly used in power applications.

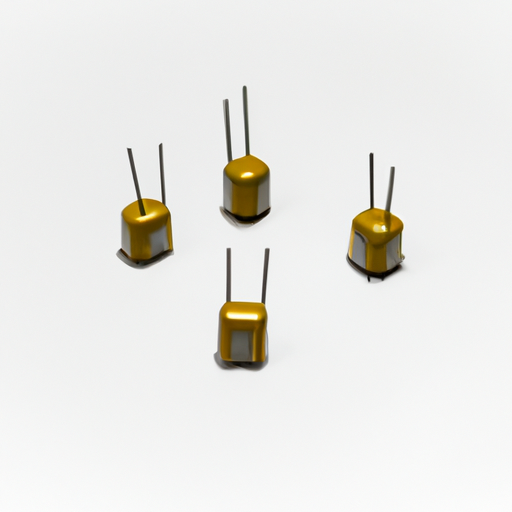

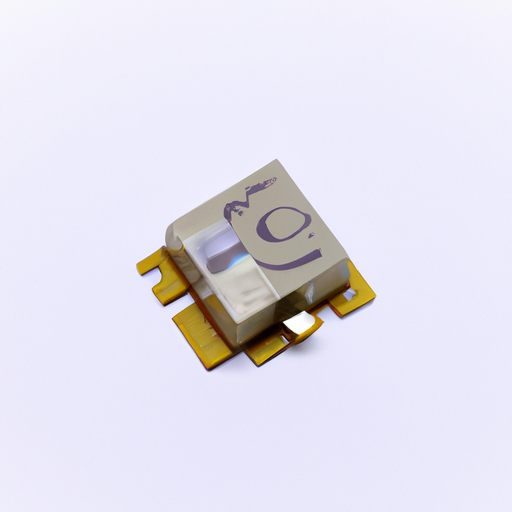

C. Ferrite-core Inductors

Ferrite-core inductors use ferrite materials, which are ceramic compounds that exhibit magnetic properties. They are particularly effective at high frequencies and are often used in RF applications and power supplies.

D. Toroidal Inductors

Toroidal inductors are wound in a circular shape around a toroidal core. This design minimizes electromagnetic interference and enhances efficiency, making them suitable for various applications, including power supplies and audio equipment.

E. Specialty Inductors

Specialty inductors, such as variable inductors and coupled inductors, are designed for specific functions. Variable inductors allow for adjustable inductance, while coupled inductors are used in applications requiring mutual inductance between two coils.

III. Key Product Standards for Inductors

Adhering to established product standards is essential for ensuring the quality and reliability of inductors. Several organizations develop and maintain these standards.

A. International Electrotechnical Commission (IEC) Standards

The IEC is a global organization that prepares and publishes international standards for electrical and electronic technologies. Relevant IEC standards for inductors include IEC 60076, which covers power transformers, and IEC 61800, which pertains to adjustable speed drives.

B. Institute of Electrical and Electronics Engineers (IEEE) Standards

The IEEE is a leading organization in the development of standards for electrical and electronic systems. Standards such as IEEE 112, which addresses the testing of inductors, are crucial for ensuring performance and reliability.

C. American National Standards Institute (ANSI) Standards

ANSI oversees the development of voluntary consensus standards for various industries in the United States. ANSI standards relevant to inductors include ANSI C63.4, which covers electromagnetic compatibility testing.

D. Underwriters Laboratories (UL) Standards

UL is a safety certification organization that develops standards for product safety. UL standards for inductors focus on safety and performance, ensuring that inductors can operate safely under specified conditions.

IV. Key Parameters and Specifications

When evaluating inductors, several key parameters and specifications must be considered to ensure they meet the requirements of a specific application.

A. Inductance Value

The inductance value, measured in henries (H), indicates the inductor's ability to store energy in a magnetic field. It is a critical parameter that influences the inductor's performance in a circuit.

B. Current Rating

The current rating specifies the maximum continuous current the inductor can handle without overheating or failing. Exceeding this rating can lead to reduced performance or damage.

C. DC Resistance (DCR)

DC resistance is the resistance of the inductor's wire when a direct current flows through it. Lower DCR values are desirable as they minimize power losses and improve efficiency.

D. Saturation Current

Saturation current is the maximum current the inductor can handle before the core material becomes saturated, leading to a significant drop in inductance. Understanding this parameter is crucial for applications that involve high current levels.

E. Self-Resonant Frequency (SRF)

The self-resonant frequency is the frequency at which the inductor's inductive reactance equals its capacitive reactance, resulting in resonance. This parameter is essential for high-frequency applications.

F. Quality Factor (Q)

The quality factor (Q) measures the inductor's efficiency, defined as the ratio of its inductive reactance to its resistance at a specific frequency. A higher Q indicates lower energy losses.

G. Temperature Coefficient

The temperature coefficient indicates how the inductance value changes with temperature. This parameter is important for applications where temperature variations are expected.

H. Insulation Resistance

Insulation resistance measures the resistance between the inductor's windings and its core or casing. High insulation resistance is essential for preventing short circuits and ensuring safety.

V. Testing and Compliance

Testing and compliance with established standards are critical for ensuring the performance and safety of inductors.

A. Testing Methods for Inductors

1. **Inductance Measurement**: This involves using specialized equipment to measure the inductance value accurately.

2. **Current Rating Tests**: These tests determine the maximum current the inductor can handle without overheating.

3. **Thermal Testing**: Thermal tests assess the inductor's performance under varying temperature conditions.

B. Compliance with Standards

Compliance with product standards is vital for ensuring that inductors meet safety and performance requirements. Certification processes often involve rigorous testing and evaluation by third-party organizations.

VI. Applications of Inductors

Inductors are used in a wide range of applications across various industries, including:

A. Power Supplies

Inductors are essential components in power supply circuits, where they help regulate voltage and current.

B. RF Applications

In radio frequency (RF) applications, inductors are used in filters, oscillators, and matching networks to ensure signal integrity.

C. Filters and Chokes

Inductors are commonly used in filters and chokes to block unwanted frequencies while allowing desired signals to pass.

D. Energy Storage

Inductors store energy in their magnetic fields, making them valuable in energy storage applications, such as in inductive charging systems.

E. Signal Processing

In signal processing circuits, inductors help shape and filter signals, contributing to improved performance and clarity.

VII. Challenges in Standardization

Despite the importance of product standards, several challenges exist in the standardization of inductors.

A. Variability in Applications

The wide range of applications for inductors leads to variability in performance requirements, making it challenging to establish universal standards.

B. Technological Advancements

Rapid technological advancements in materials and design can outpace existing standards, necessitating continuous updates and revisions.

C. Global Market Considerations

As the electronics market becomes increasingly globalized, harmonizing standards across different regions and countries poses a significant challenge.

VIII. Future Trends in Inductor Standards

The future of inductor standards is likely to be shaped by several emerging trends.

A. Emerging Technologies

Advancements in technology, such as the development of new materials and manufacturing techniques, will influence the design and performance of inductors.

B. Sustainability and Environmental Considerations

As the electronics industry moves towards more sustainable practices, standards will need to address environmental concerns, including the use of eco-friendly materials and manufacturing processes.

C. Innovations in Materials and Design

Innovations in materials, such as the use of nanomaterials and advanced composites, will lead to the development of more efficient and compact inductors.

IX. Conclusion

In conclusion, product standards for inductors play a vital role in ensuring the quality, reliability, and safety of these essential components in electronic circuits. By adhering to established standards, manufacturers can produce inductors that meet the diverse needs of various applications while ensuring compliance with safety regulations. As technology continues to evolve, the importance of these standards will only grow, paving the way for innovations that enhance the performance and sustainability of inductors in the electronics industry.