An article to help you understand what resistor starting is

Understanding Resistor Starting: A Comprehensive Guide

I. Introduction

In the realm of electrical engineering, the methods used to start electric motors are crucial for ensuring efficiency and reliability. One such method is resistor starting, a technique that has gained prominence in various industrial applications. This article aims to demystify resistor starting, exploring its mechanisms, advantages, disadvantages, and applications. By the end, readers will have a comprehensive understanding of this important electrical starting method.

II. Basics of Electrical Starting Methods

A. Overview of Starting Methods for Electric Motors

Electric motors are essential components in countless applications, from household appliances to industrial machinery. The method used to start these motors can significantly impact their performance and longevity. Here are some common starting methods:

1. **Direct On-Line (DOL) Starting**: This is the simplest method, where the motor is connected directly to the power supply. While it is cost-effective, it can lead to high inrush currents that may damage the motor.

2. **Star-Delta Starting**: This method reduces the starting current by initially connecting the motor in a star configuration, which limits the voltage across the motor windings. After a brief period, the motor is switched to a delta configuration for normal operation.

3. **Autotransformer Starting**: This technique uses an autotransformer to reduce the voltage supplied to the motor during startup, thereby limiting the inrush current.

B. Introduction to Resistor Starting

1. **What is Resistor Starting?**: Resistor starting involves the use of resistors in the starting circuit to limit the current flowing to the motor during startup. This method is particularly useful for large induction motors, where controlling the inrush current is critical.

2. **Historical Context and Development**: Resistor starting has evolved over the years, with advancements in resistor technology and circuit design enhancing its effectiveness. Initially used in specific applications, it has become a standard practice in many industries.

III. The Mechanism of Resistor Starting

A. How Resistor Starting Works

1. **Role of Resistors in Starting Circuits**: In a resistor starting circuit, resistors are placed in series with the motor during startup. This configuration limits the current, allowing the motor to start smoothly without experiencing excessive torque or heat.

2. **Sequence of Operation**: The starting process typically involves the following steps:

- The motor is energized, and current flows through the resistors.

- As the motor accelerates and reaches a certain speed, the resistors are gradually bypassed.

- Once the motor reaches its rated speed, the resistors are completely removed from the circuit.

B. Types of Resistor Starting Circuits

1. **Fixed Resistor Starting**: In this configuration, a set of fixed resistors is used to limit the current. This method is straightforward but may not provide optimal performance for all applications.

2. **Variable Resistor Starting**: This approach allows for the adjustment of resistance based on the specific requirements of the motor and application. Variable resistors can be manually or automatically adjusted to optimize performance.

C. Components Involved

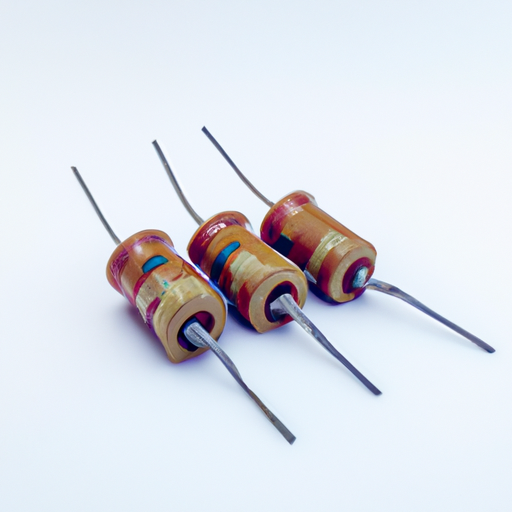

1. **Resistors**: The primary component in resistor starting, these devices are designed to handle high currents and dissipate heat effectively.

2. **Contactors**: These electromechanical switches control the flow of electricity in the circuit, enabling the connection and disconnection of the resistors.

3. **Motor Protection Devices**: These devices safeguard the motor from overloads and faults, ensuring safe operation throughout the starting process.

IV. Advantages of Resistor Starting

A. Reduced Inrush Current

One of the most significant benefits of resistor starting is the reduction of inrush current. By limiting the initial current, the method protects the motor and associated equipment from damage, extending their lifespan.

B. Improved Torque Control

Resistor starting allows for better control of the starting torque. This is particularly important in applications where high starting torque can lead to mechanical stress or damage.

C. Enhanced Motor Life and Reliability

By minimizing the thermal and mechanical stresses associated with high inrush currents, resistor starting contributes to improved motor reliability and longevity.

D. Applications in Various Industries

Resistor starting is widely used in industries such as mining, manufacturing, and water treatment, where large motors are common and the need for controlled starting is paramount.

V. Disadvantages of Resistor Starting

A. Heat Generation and Dissipation Issues

While resistor starting reduces inrush current, it does generate heat during operation. Proper heat dissipation measures must be in place to prevent overheating and potential damage to the resistors.

B. Complexity of Circuit Design

The design of resistor starting circuits can be more complex than simpler methods like DOL starting. This complexity may require specialized knowledge and skills for installation and maintenance.

C. Cost Considerations

The initial cost of implementing resistor starting systems can be higher than other starting methods. However, this cost may be offset by the long-term benefits of reduced maintenance and increased motor life.

D. Limitations in High-Power Applications

In very high-power applications, resistor starting may not be the most efficient method. Alternative starting techniques may be more suitable for these scenarios.

VI. Applications of Resistor Starting

A. Common Industries Utilizing Resistor Starting

1. **Mining**: Large motors used in mining operations often require controlled starting to prevent mechanical failures.

2. **Manufacturing**: In manufacturing processes, where large machinery is common, resistor starting helps maintain operational efficiency.

3. **Water Treatment**: Pumps and motors in water treatment facilities benefit from the controlled starting provided by resistor starting.

B. Specific Use Cases

1. **Large Induction Motors**: Resistor starting is particularly effective for large induction motors, where inrush current can be a significant concern.

2. **Pumps and Fans**: These applications often require smooth acceleration to prevent damage to the system.

3. **Conveyors**: In conveyor systems, controlled starting helps maintain the integrity of the materials being transported.

VII. Comparison with Other Starting Methods

A. Resistor Starting vs. Direct On-Line Starting

While DOL starting is simpler and less expensive, it can lead to high inrush currents that may damage the motor. Resistor starting, on the other hand, provides a controlled start, reducing the risk of damage.

B. Resistor Starting vs. Star-Delta Starting

Star-delta starting is effective for reducing starting current but may not provide the same level of torque control as resistor starting. The choice between the two methods depends on the specific application requirements.

C. Resistor Starting vs. Autotransformer Starting

Autotransformer starting is another method for reducing starting current, but it may not offer the same flexibility in torque control as resistor starting. Each method has its advantages and is suited for different applications.

D. Situational Analysis: When to Use Resistor Starting

Resistor starting is ideal for applications where controlled starting is critical, such as large induction motors, pumps, and conveyors. It is particularly beneficial in industries where equipment longevity and reliability are paramount.

VIII. Future Trends in Resistor Starting Technology

A. Innovations in Resistor Design

Advancements in resistor technology are leading to more efficient and compact designs, improving the overall performance of resistor starting systems.

B. Integration with Smart Technologies

The integration of smart technologies into resistor starting systems allows for real-time monitoring and control, enhancing efficiency and reliability.

C. Environmental Considerations and Sustainability

As industries move towards more sustainable practices, resistor starting systems are being designed with energy efficiency in mind, reducing their environmental impact.

IX. Conclusion

In summary, resistor starting is a vital method for starting electric motors, offering numerous advantages such as reduced inrush current, improved torque control, and enhanced motor life. While it has its disadvantages, the benefits often outweigh the drawbacks, making it a preferred choice in many industrial applications. As technology continues to evolve, resistor starting will likely play an increasingly important role in modern electrical systems. For those interested in further exploring this topic, numerous resources are available for deeper learning.

X. References

A. Suggested Reading Materials

- "Electric Motor Control" by Stephen L. Herman

- "Electrical Machines, Drives, and Power Systems" by Theodore Wildi

B. Relevant Standards and Guidelines

- IEEE Standards for Electric Motors

- National Electrical Code (NEC) Guidelines

C. Online Resources for Further Study

- IEEE Xplore Digital Library

- National Electrical Manufacturers Association (NEMA) Website

This comprehensive guide provides a thorough understanding of resistor starting, its mechanisms, advantages, disadvantages, and applications, equipping readers with the knowledge to make informed decisions in their electrical engineering endeavors.