What is the mainstream Shandong resistor production process?

What is the Mainstream Shandong Resistor Production Process?

I. Introduction

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling current flow and voltage levels. They are essential for the proper functioning of a wide range of devices, from simple household electronics to complex industrial machinery. Shandong, a province in eastern China, has emerged as a significant hub for resistor production, contributing to both domestic and global markets. This article aims to explore the mainstream resistor production process in Shandong, shedding light on the methods, technologies, and innovations that define this vital industry.

II. Understanding Resistors

A. Definition and Function of Resistors

A resistor is a passive electronic component that resists the flow of electric current, creating a voltage drop across its terminals. This property is essential for managing electrical signals in circuits, ensuring that components receive the appropriate voltage and current levels. Resistors are characterized by their resistance value, measured in ohms, and are used to limit current, divide voltages, and protect sensitive components from damage.

B. Types of Resistors Commonly Produced

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in various applications, including voltage dividers and current limiters.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow users to adjust the resistance value, making them ideal for applications like volume controls and tuning circuits.

3. **Specialty Resistors**: This category includes precision resistors, high-power resistors, and temperature-sensitive resistors, designed for specific applications in industries such as automotive, telecommunications, and medical devices.

C. Applications of Resistors in Various Industries

Resistors find applications across multiple sectors, including consumer electronics, automotive, telecommunications, and industrial automation. They are integral to devices such as smartphones, computers, electric vehicles, and medical equipment, highlighting their importance in modern technology.

III. The Shandong Resistor Industry Landscape

A. Historical Context of Resistor Manufacturing in Shandong

Shandong's resistor manufacturing industry has evolved significantly over the past few decades. Initially focused on basic production, the industry has grown to incorporate advanced technologies and materials, positioning itself as a leader in the global market.

B. Key Players in the Shandong Resistor Market

Several prominent manufacturers operate in Shandong, contributing to the province's reputation as a resistor production hub. These companies invest in research and development, ensuring they remain competitive in an ever-evolving market.

C. Economic Significance of the Resistor Industry in Shandong

The resistor industry plays a vital role in Shandong's economy, providing employment opportunities and contributing to the province's industrial output. As demand for electronic components continues to rise, the resistor sector is poised for further growth.

IV. The Mainstream Resistor Production Process

A. Raw Material Selection

The production of resistors begins with the careful selection of raw materials. Common materials include carbon, metal film, and wire wound elements, each chosen for their specific electrical properties.

1. **Types of Materials Used**: Carbon resistors are known for their stability and cost-effectiveness, while metal film resistors offer higher precision and lower noise. Wire wound resistors are preferred for high-power applications due to their ability to handle significant heat.

2. **Quality Control Measures for Raw Materials**: Ensuring the quality of raw materials is critical. Manufacturers implement stringent quality control measures, including supplier audits and material testing, to guarantee that only the best materials are used in production.

B. Manufacturing Steps

The resistor manufacturing process involves several key steps:

1. **Material Preparation**:

- **Grinding and Mixing of Raw Materials**: The raw materials are ground into fine powders and mixed to achieve the desired resistive properties.

- **Forming the Resistor Body**: The mixed materials are then shaped into the desired form, typically using molds or extrusion techniques.

2. **Resistor Element Fabrication**:

- **Application of Resistive Materials**: The resistive material is applied to the formed body, often using techniques such as screen printing or sputtering.

- **Techniques for Achieving Desired Resistance Values**: Manufacturers adjust the thickness and composition of the resistive layer to achieve specific resistance values.

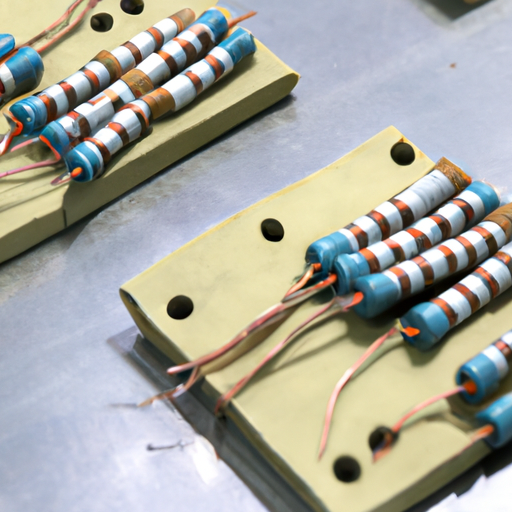

3. **Assembly Process**:

- **Mounting the Resistor Elements**: The resistor elements are mounted onto substrates or leads, depending on the type of resistor being produced.

- **Soldering and Connecting Leads**: Soldering is performed to ensure secure electrical connections, which is critical for the resistor's performance.

4. **Encapsulation and Coating**:

- **Protective Coatings and Their Importance**: Resistors are coated with protective materials to shield them from environmental factors such as moisture and dust.

- **Methods of Encapsulation**: Various encapsulation techniques, including epoxy and ceramic coatings, are employed to enhance durability.

C. Quality Control and Testing

Quality control is paramount in resistor production. Manufacturers conduct in-process quality checks at each stage of production to identify and rectify any issues early on.

1. **In-Process Quality Checks**: These checks ensure that materials and components meet specified standards throughout the manufacturing process.

2. **Final Testing Procedures**: Once production is complete, resistors undergo rigorous testing to verify their resistance values, tolerance levels, and overall performance.

3. **Certification and Compliance with Industry Standards**: Compliance with international standards, such as ISO and RoHS, is essential for manufacturers to ensure their products are safe and reliable.

V. Technological Innovations in Resistor Production

A. Advances in Materials Science

Recent advancements in materials science have led to the development of new resistive materials that offer improved performance, stability, and miniaturization. These innovations enable manufacturers to produce smaller, more efficient resistors.

B. Automation and Robotics in Manufacturing

The integration of automation and robotics in the manufacturing process has increased efficiency and precision. Automated systems can perform repetitive tasks with high accuracy, reducing the risk of human error and improving production rates.

C. Environmental Considerations and Sustainable Practices

As environmental concerns grow, the resistor industry is adopting sustainable practices. Manufacturers are exploring eco-friendly materials and processes, reducing waste, and minimizing their carbon footprint.

VI. Challenges Facing the Shandong Resistor Industry

A. Competition from Global Manufacturers

The Shandong resistor industry faces stiff competition from manufacturers in other countries, particularly in regions with lower production costs. To remain competitive, Shandong manufacturers must focus on innovation and quality.

B. Supply Chain Issues

Global supply chain disruptions can impact the availability of raw materials and components, posing challenges for manufacturers. Building resilient supply chains is essential for maintaining production continuity.

C. Regulatory Challenges and Compliance

Navigating regulatory requirements can be complex, especially for companies looking to export their products. Compliance with international standards is crucial for accessing global markets.

VII. Future Trends in Resistor Production

A. Predictions for the Evolution of Resistor Technology

The future of resistor technology is likely to see continued advancements in materials and manufacturing techniques. Innovations such as smart resistors, which can adapt their resistance based on environmental conditions, may emerge.

B. The Role of Shandong in the Global Resistor Market

Shandong is expected to maintain its position as a key player in the global resistor market, leveraging its manufacturing capabilities and expertise to meet growing demand.

C. Potential for Growth and Innovation in the Industry

As technology evolves, the resistor industry will continue to explore new applications and markets, driving growth and innovation in the sector.

VIII. Conclusion

The resistor production process is a complex and vital aspect of the electronics industry, with Shandong playing a significant role in this landscape. The province's commitment to quality, innovation, and sustainability positions it as a leader in the global resistor market. As the industry continues to evolve, Shandong's manufacturers are well-equipped to meet the challenges and opportunities that lie ahead.

IX. References

A comprehensive list of relevant literature, industry reports, and expert opinions will provide further insights into resistor technology and manufacturing processes. For those interested in delving deeper, additional resources are available for further reading on this essential component of modern electronics.